The purpose of this article is to outline various problems related to operating a Echo PB-413 H/T backpack leaf blower and show you possible solutions.

YOU MAY ALSO WANT TO READ:

- Basic Maintenance

- Symptoms and Repair Solutions (You are here)

- Zama C1M-K77 Carburetor Rebuild

- Zama C1M-K77 Carburetor Adjustment

- Gas in the air filter

- Non-OEM vs OEM Air Filters

- Resource Page for Echo PB-413H Backpack Leaf Blower

TABLE OF CONTENTS

- Engine does not start – soft pop, false start sound

- Engine starts, and quickly dies

- Engine starts, dies when throttle is applied

- Engine starts, only with starter fluid

- Engine starts, for few minutes then dies

- Engine starts, stalls at high power / speed

- Engine starts, only if primer bulb is pumped

- Engine starts, bogs down/dies at full throttle

- Engine starts, power is lacking

- Engine starts, runs only on full choke

- Engine starts, RPM fluctuates on its own

- Engine starts, runs rough

- Engine starts, and runs well when cold; when choke is open, idle becomes rough

- Pullcord is stuck

- Fuel mixture in the air filter housing / siphons gas into air filter

ENGINE DOES NOT START – SOFT POP OR FALSE START SOUND

PROBABLE CAUSE:Flooded engine.

- Starter rope was pulled several times while the choke was in the closed “COLD” position and the engine did not start;

- If you heard a faint engine pop or false start then the engine is most likely flooded;

- To un-flood the engine, make sure the choke is down in the “RUN” position;

- Set the throttle to max speed (orange lever should be pushed all the way down towards the rabbit sign);

- Pull the starter rope several times until the engine starts;

ENGINE STARTS – QUICKLY DIES

PROBABLE CAUSE:Collapsing fuel line(s), damaged diaphragm(s) or fuel lines reversed.

- Gently squeeze the fuel supply and return lines to confirm that they are firm with no soft spots, cracks, kinks or holes;

- Verify that fuel lines are connected properly (i.e. a fuel supply line is larger in diameter than the return line)

- Replace spark plug, gas filter and air filter;

- Replace the fuel lines;

- If the problem is not resolved, rebuild the carburetor using an appropriate rebuild kit;

PULL CORD IS STUCK

PROBABLE CAUSE:Engine cylinder has compression/vapor lock / Engine seized / Pullcord broken.

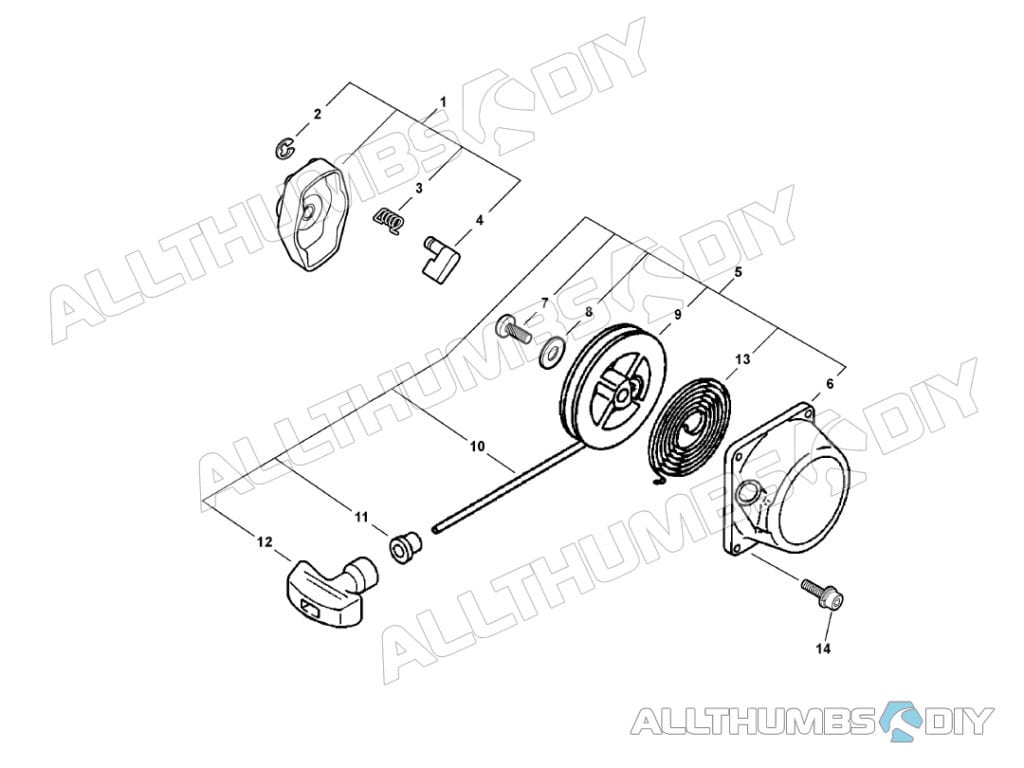

| ITEM | Part # | Desc. |

| 01 | 17720206210 | STARTER PAWL ASY INCLUDES ITEMS 2-4 |

| 02 | 90070000004 | E-RING |

| 03 | 17723440630 | SPRING, RETURN |

| 04 | 17721840630 | PAWL, STARTER |

| 05 | 17720021260 | STARTER ASY INCLUDES ITEMS 6-13 |

| 06 | 17723206210 | CASE, STARTER |

| 07 | 17723640630 | SCREW |

| 08 | 17721440630 | WASHER |

| 09 | 17721511120 | DRUM, STARTER |

| 10 | 17722611120 | ROPE, STARTER – 4X1350mm REPOWER BULK OPTION: 99944450000 |

| 11 | 17722742030 | GUIDE, ROPE |

| 12 | 17722801110 | GRIP, STARTER |

| 13 | 17722011120 | SPRING, REWIND |

| 14 | 90016304018 | SCREW 4X18 |

*Numbers expressed in the two digit format (i.e 06) are item reference numbers in the above diagram

- Remove the spark plug;

- Add 1/8 oz of 2-cycle engine oil into the spark plug hole to lubricate the internal parts;

- Use a metric Allen wrench to remove 4 bolts (14) holding down the starter case/cover (06);

- With the crankshaft/pullcord bracket exposed, use a large pipe wrench to gently turn the shaft counter-clockwise 20 times; listen closely for any strange noises (i.e. metal scraping, etc.) from the engine;

- If you have a difficult time turning the wrench, the engine is probably seized (in which case, stop the procedure and bring it to your local dealer);

- Reinstall the case cover;

- Gently pull the rope 3/4 way, about 20 times;

- Remove as much engine-oil buy using cotton swabs;

- If the rope pulls okay, reinstall the spark plug/cable; if the rope does not pull, you will probably need to replace the drum starter (09), starter rope (10) and/or rewind spring (13);

- Set throttle lever at mid-to-low idle and pump the primer bulb 2-3 times;

- Gently pull the rope 3/4 way few times to start the engine; let is run for 5-10 minutes to burn off any leftover oil (exhaust will spit out white smoke);

- If that doesn’t work, remove the muffler assembly for visual inspection of the engine (you can see parts of the cylinder/piston via exhaust port;

- If the piston looks scratched and/or black, the engine may be seized;

- Replacing a seized engine might be more expensive than just replacing;

- Contact your local Echo dealer for service;

- If the piston looks good, the pullcord (recoil) assembly needs to be replaced;

ENGINE STARTS, RUNS ONLY ON FULL CHOKE

PROBABLE CAUSE: Air is getting through place(s) other than air filter

- Improper air penetration will cause other symptoms like rough idle, fluctuating engine RPM, etc.

- Most common trouble area is the fuel supply hose inside the tank;

- Check the supply hose to ensure that there are no holes or cracks;

- If all basic maintenance tasks are done, carburetor overhaul is recommended;

- Make sure to purchase the rebuild kit prior to taking apart the carburetor (read this article);

ENGINE STARTS, RUNS WELL COLD, WHEN CHOKE IS OPEN, IDLE BECOMES ROUGH

PROBABLE CAUSE: Adjustment to LO speed mixture screw may be required

- LO speed may be set either too lean or too rich which cause engine idle to become rough when choke is off with engine warmed up;

- Read Adjusting Zama C1M-K77 Carburetor on Echo PB-413H Backpack Leaf Blower for a detailed how-to instructions;

ENGINE DOES NOT START, PURGE/PRIMER BULB WILL NOT FILL WITH GAS

PROBABLE CAUSE: Faulty fuel filter, faulty carburetor check-valve

- The primer bulb pulls fuel from the carb into the bulb and dumps back to the tank;

- Check the fuel supply and return lines to ensure that they are not cracked, bent or kinked;

- Verify that fuel lines are connected to proper places;

- Visually verify that fuel filter is resting on the bottom of the gas tank (so that it can draw fuel);

- Add fuel mixture to the tank so that the fuel level is half full / full;

- If the problem remains, carburetor will need to be rebuilt;

- Make sure to purchase the rebuild kit prior to taking apart the carburetor (read this article);

ENGINE STARTS, ONLY IF PRIMER BULB IS PUMPED, REBUILT CARBURETOR

PROBABLE CAUSE: Faulty fuel line, faulty carburetor internal components

- Confirm that fuel lines are not kinked, bent or cracked;

- Replace fuel filter;

- Check muffler guide and exhaust port;

- If problem remains, re-build the carburetor;

- Make sure to purchase the rebuild kit prior to taking apart the carburetor (read this article);

ENGINE STARTS, BOGS DOWN / DIES AT FULL THROTTLE

PROBABLE CAUSE: Fuel mixture is too rich

- Confirm that exhaust port and spark arrestor are clean;

- Check that spark plug is clean and properly gapped;

- Fuel mixture settings on the carburetor needs to be adjust;

- Please refer to the

- Zama C1M-K77 Carburetor Adjustment

article

ENGINES STARTS, MUST HAVE CHOKE OPEN

PROBABLE CAUSE: Fuel mixture is running very lean

- Need to adjust the fuel mixture setting;

- Please refer to the Zama C1M-K77 Carburetor Adjustment article;

JUMP TO THE TOP

=============================================================

PROBABLE CAUSE:

JUMP TO THE TOP

=============================================================

To adjust setup, start with at least a half tank of fuel, and

Blower bogs down and kills at full throttle

Cleaned carb, cleaned exhaust screen, cleaned filter, checked plug proper spacing. starts on the second pull every time, but soon as I turn the throttle all the way up it bogs down and kills. almost like it got flooded but still starts up two pulls later

Turn the high speed and low speed mixture screws right in[gently]then out 2.5 turns.start it up,screw the idle screw up till it will idle,then adjust low speed mixture screw in or out so you get the highest idle.keep lowering the idle so as you adjust the screw,it wont get it any higher in revs.so by now it should idle.next,open the throttle wide,and adjust the high speed screw until you get maximum revs..then,turn screw 1/4 turn out.that makes it slightly richer,cooling the plug with droplets of petrol.you dont want it lean.if it wont rev fully,check the fuel filter.they get dirty quite often

messing with welch plug is not a good idea:

f the fuel lines, spark arrestor, sparkplug and carb check out OK, (as mine did) and if it will rev up with the choke partially on, here’s the fix:

cho carbs have a little black plastic plug covering the High speed adj screw..CA air pulotion control bs..So get that little black blug out and give the screw a little turn open and u should be good to go..It worked for me..on a PBL 251 blower..My Echo weed wacker has the carb also..Go to Echos site and download the parts break down for your unit and look at the carb page..You will see the plug and HS,screw..happing wacking and blowing

There is a small plastic plug pressed into a slightly larger brass plug located in the body of the carburetor, surrounded mostly by the white plastic primer housing (between the fuel in and out hose connections). Pry out the plastic plug with a pick and you will find the high-speed adjustment needle. You’ll have to back it out a bit to richen the mixture. Using a tiny screwdriver, start the engine and find the point where the engine runs at maximum speed (don’t leave it here as you could run the risk of running the engine a bit on the lean side, causing premature cylinder wear). Then, back out the screw a bit more until the engine speed starts to drop a bit. Try revving the engine a few times with the throttle trigger and if it’s nice and responsive, you’re all set

Engines stalls at high power / speed

probabaly fuel starvation caused by:

damaged primer bulb

clogged fuel filter

damaged fuel lines

clogged metering diaphragm

FUEL/AIR MIXTURE IN THE AIR FILTER HOUSING

—-

- replace air filter as dirty air filter may make the engine run rich with fuel;

- take apart the carburetor and clean internal passages (jet) with compressed air;

- The diaphgram may look good and flexible, but it can be deceiving and not act as a fuel pump as it should because it has become too hard and will cause hard starting,start and run and shut off, etc.;

- use a laquer thinner type cleaner to clean and dissolve the laquer build-up in the float and needle jet passages.

Be sure to remove all plastic and rubber par; - ;

- ;

ECHO LEAF BLOWER DIES WHEN THROTTLE IS APPLIED

This solution may work when attempting to accelerate from idle, engine makes a deep throaty sound then dies.

- Check to make sure the spark arrestor screen is not clogged;

- Check to make sure the exhaust port is not blocked;

- Check to make sure the fuel line inside the tank is in good condition (no holes);

- There should be enough fuel to submerge the fuel filter;

- Take apart the carburetor to ensure that fuel metering lever is clean;

- Replace metering diaphragm and fuel diaphragm;

FLUCTUATING ENGINE RPM

This solution is when the engine RPM fluctuates on its own wen throttle is wide open.

- Ensure that choke lever is not loose (stays in the desired position);

- Check fuel and return lines to make sure that there are no cracks, kinks, holes, etc.

- Drain the tank and refuel with 89 or higher octane with proper 2-cycle engine oil mixture

- Check the spark arrestor screen and exhaust port for clogs

- Rebuild the carburetor;

SOLUTIONS – ENGINE WILL START ONLY WITH STARTER FLUID AND DIES

Most likely cause: Fuel problem

- Check fuel and return lines to make sure that there are no cracks, kinks, holes, etc.

- Drain the tank and refuel with 89 or higher octane with proper 2-cycle engine oil mixture

- Temporarily remove the fuel filter and attempt to start;

- Adjust carb fuel/air mixture screws;

- Rebuild the carburetor;

SOLUTIONS – LEAF BLOWER STARTS AND DIES OUT IN FEW MINUTES

It sounds like the carburetor is running out of fuel.First make sure the tank is full then loosen or remove the gas cap when it starts sputtering to see if that corrects the problem. Then with engine off remove the fuel line that goes from the tank to the fuel pump,hold it low and see if any fuel flows out of it,if not lightly blow air backwards to the tank,(with fuel cap off),then see if the line is plugged. Next remove the fuel line that goes to carburetor from the fuel pump,crank the engine and see if any fuel flows,if so the carburetor should be cleaned by removing it and disassembling it.

- Check choke lever position. Make sure that the choke is working and not in the COLD start position.

- Check to make sure both fuel supply and return lines are not clogged, cracked, bent, kinked, etc.

- Gap cap might be defective; temporarily loosen it to see if the engine will continue to run; if loosening solves the problem, replace the gas cap

- Carburetor might be out of adjustment and needs to be adjusted

- Carburetor might have dirt or debris and would need to be cleaned out and rebuilt.

- Ignition module failure, the module/coil would need to be tested and possibly replaced

SOLUTIONS – ENGINE RUNS BUT LACKS POWER

Usually

- Check compression with tool – 60 psi

- Check spark in spark plug

- Rebuild carb

SOLUTIONS – LEAF BLOWER RUNNING ROUGH

Usually, a leaf blower that is couple of years old or more has varnish and other gunk that may clog the carburetor. might be clogged. I do not like to use carb cleaner or engine cleaner (i.e. Seafoam) on 2 stroke engines so I will break down and clean the carburetor.

SOLUTIONS – LEAF BLOWER NOT REACHING MAXIMUM RPM / BOGGING DOWN

WHERE TO BUY PARTS

WRAP UP

That pretty much does it for this project. With a manual interlock kit, I am able to manage whichever circuit I want to supply power to without worrying about overloading the portable generator. Not as convenient as the standby generator, but I am not a big fan of all the electronics in such units so this setup works for me.

If you have any questions, please leave a comment below.

Thanks and good luck with your DIY project!