Installing a New Subpanel is a multi-part series article, broken into Part 1, Part 2, Part 3, Part 4 and Part 5.

CABLE CONNECTION

Step 10 – Connect Cable

Before inserting the cable into the panel, I carefully removed the cable sheathing by making a small incision to determine the ground wire. Using a very sharp utility knife, I cut the sheathing slowly by following the ground wire. This step was necessary to ensure that I did not damage the individual insulation for the remaining 3 wires.

I then routed the unsheathed wires through the NM connector then tightened the NM connector screws. I made sure that I did not OVERTIGHTENED the screws because over tightening can potentially damage the wires.

Step 11 – Connecting wires to the main breaker

Because I was using an aluminum wires, I had to take some extra steps. For copper wires, I could have skipped those steps.

First, I measured the distance between the NM connector to the main breaker termination points and removed the excess wires by using my heavy-duty wire cutter. Then, I removed approximately 1 to 1.5″ of the insulation from each wires. Using the fine grit sandpaper, I polished the exposed ends to remove any oxidation (invisible grease, etc.). I then generously applied Noalox from IDEAL Industries which prevents and oxidation/corrosion. Finally, wires were attached to the proper termination points.

Step 11 – Install GFCI receptacle

To wrap up the basement part of the project, I installed a GFCI by:

- Attaching the offset NM connector to the 4″ square junction box

- Punching a knockout hole at the bottom of the panel

- Carefully aligning and connecting the offset NM connector to the panel

- Insert a scrap piece of 20 Amp wire (12AWG, ~ 3ft long)) from the junction box to the panel’s circuit breaker location

- Connect Ground wire to the ground bus bar; neutral to the neutral bus bar

- Connect black wire to the circuit breaker then insert into the circuit breaker slot

- Connect black wire to the GFCI’s brass screw

- White wire to the GFCI’s silver screw

- Ground to green screw.

- For safety reasons, tightly wrap a black electrical tape around the GFCI twice

- Remove both the “rabbit ear” and center tab so that GFCI can be attached to the metal cover

- Screw in the GFCI from the metal cover side

- Screw the metal cover to the junction box and I was done!

Step 12 – Working with the Main Panel

Before I removed the cover to my main panel, I turned off each circuits individually, then turned off the main breaker.

With the panel cover removed, I was EXTREMELY CAREFUL working inside the panel because even with the main breaker off, the service cable terminations from the meter REMAINED HOT

Step 13 – Cable attachment

After determining that the best way to route my new cable was through the bottom right side of the main panel, I:

- Punched out a knockout hole from the main panel, then installed a NM connector

- Roughly estimated the cable length, then cut off the excess (TIP: Always gauge from the entry point to the farthest termination point)

- Carefully removed the cable sheathing, using a sharp utility knife.

- Inserted, stripped, polished, applied noalox and terminated wires.

- Although you can terminate neutral and ground wires on the same bus, I terminated them separately for better cable management. Also, the neutral bus bars have a limited number of large slots that are able to accept 2AWG wires. I looked for larger screws to identify them.

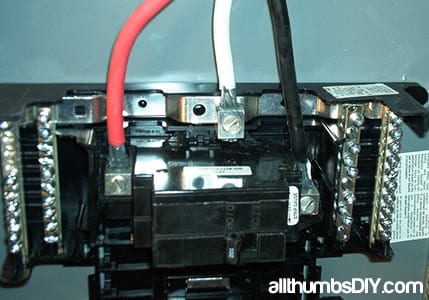

- Finally, I attached the black and red “hot” wires to the 100 Amp breaker and installed on the main panel

Please note that the picture on the left was taken just before the Noalox application.

At this point, the only remaining task was to remove correspondinh metal slot covers from the cover panel before putting it back on the panel box.

Part 6: Wrap-Up

Now that all connections are made, I turned on the sub panel main breaker first, then the circuit breaker at the main panel, then tested the new sub panel by plugging in the lamp to the sub panel’s GFCI outlet. I also plugged in my 3-prong light to ensure that GFCI was properly wired. Upon finishing my testing, I created a new set of labels as well as updated my electric map.

INSPECTIONS

After everything was tested, I cleaned up the mess since I knew that making sure everything was neat and clean increased my chance of passing the inspection (which it did).

I had to make a note on the panel to make sure that I check and re-tighten the aluminum connection twice a year. This is because copper and aluminum heat and cool at a different rate, potentially loosening the connection.

Well, that’s how I installed my sub panel! Based on the estimates I received from licensed electricians, I saved more than $1,100.00 (USD)!

RELATED ARTICLES

- Installing a new Subpanel – Part 1

- Installing a new Subpanel – Part 2

- Installing a new Subpanel – Part 3

- Installing a new Subpanel – Part 4

- Installing a new Subpanel – Part 5

Dan

Thursday 11th of December 2014

I'm putting is a sub panel as described here. One thing I'm not clear on is my sub is a single phase yet the main breaker is 100amp and two hots go to the subpanel. I will run anything you say by the code guys. I like to have some idea before I ask them questions.

kevin

Saturday 27th of December 2014

@Dan-

I am not sure of your exact setup, if I recall correctly, I used an Service Entrance (SER 2-2-2-4) aluminum cable with 2 hot legs (black and red) which was tied back at the main panel with a Square D QO double pole 100 amp breaker (QO 2100CP).

As you stated, I would recommend talking it over with your local code guys.

Thanks!

Kevin

joe

Friday 3rd of August 2012

Looking to add a subpanel to my new home. i purchased the Cutler hammer because I am familiar with the quality of the product. It was great finding your site.. Its helping me alot with all of the research.. Thanks a million..

Joe

kevin

Saturday 4th of August 2012

Thanks Joe and keep us posted about your project!

Installing a new Subpanel – Part 1

Monday 16th of July 2012

[...] Installing a new Subpanel – Part 5 [...]

Installing a New Subpanel – Part 3

Monday 16th of July 2012

[...] Installing a new Subpanel – Part 5 [...]

Jack Perry

Sunday 15th of July 2012

This article was very informative, thank you for taking the time to share this information. One question I did have is where did you purchase the Square D QO 100 amp Value Pack ? I’ve been searching the web, but haven’t been able to find it.

kevin

Sunday 15th of July 2012

@Jack-

Thanks for the kind words. I purchased my Square D QO 100 Amp value pack from a local Home Depot store as homedepot.com not carry them (although they have the option to purchase online then pickup in-store). The product link is here (http://www.homedepot.com/h_d1/N-5yc1v/R-100191925/h_d2/ProductDisplay?catalogId=10053&langId=-1&keyword=square+d+100+amp+value+pack&storeId=10051)