BACKGROUND

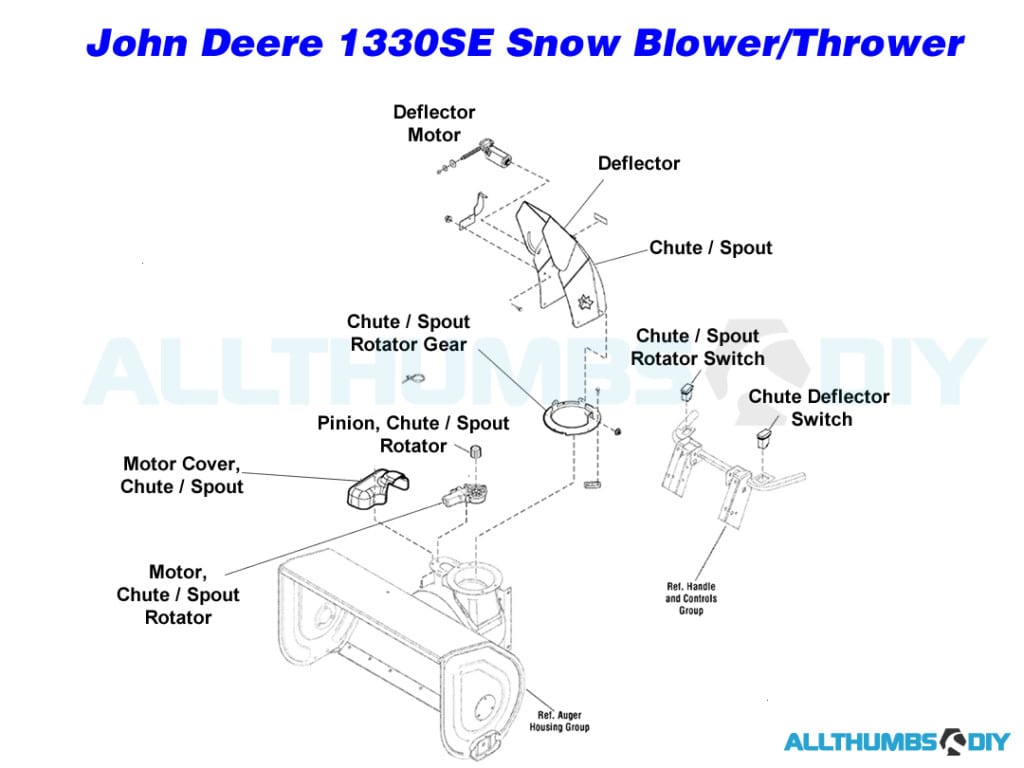

There are three major components to controlling the snow discharge chute:

- Chute Control Switch – rotates the chute clockwise or counter-clockwise;

- Wiring Harness – conducts electricity;

- Linear Chute Motor – responds to input from the switch to rotate the “teeth ring” around the chute forward or backward;

This article focuses on the discharge chute/spout control switch because the wiring harness and motor are far less likely to fail.

CHUTE CONTROL SWITCH

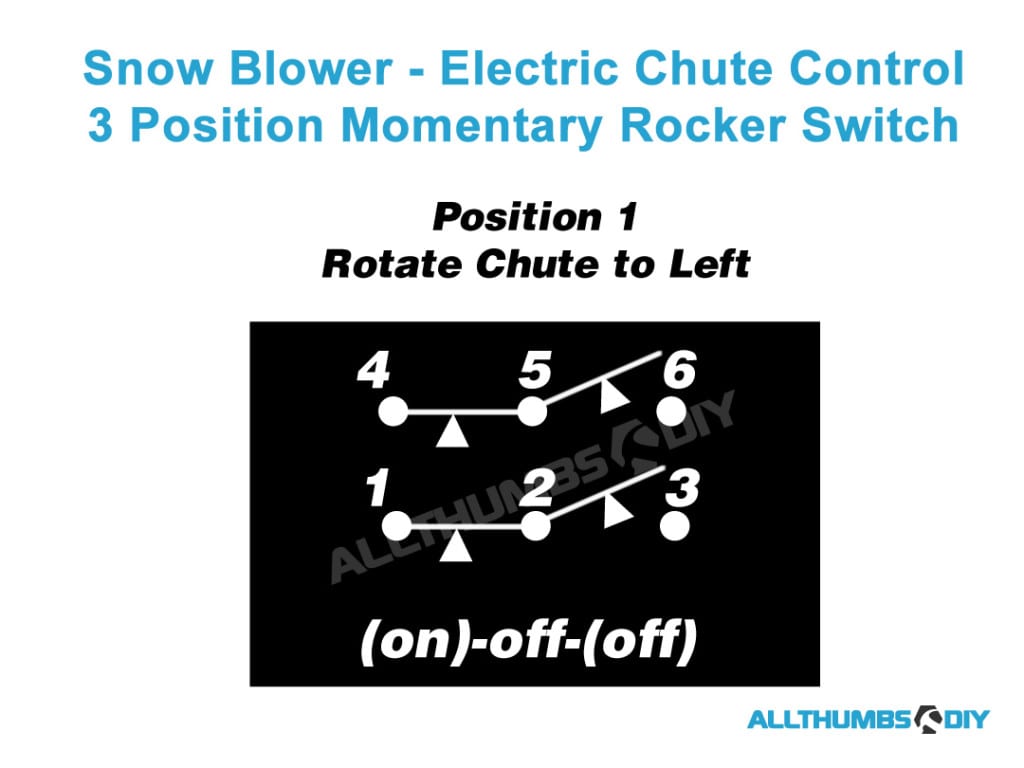

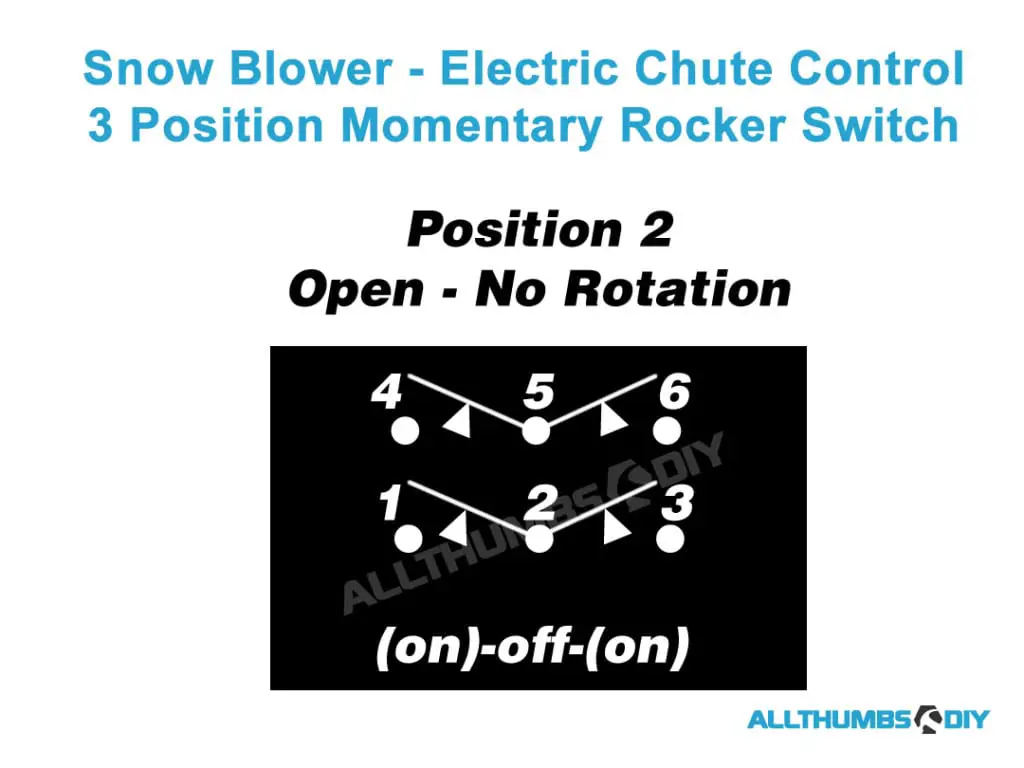

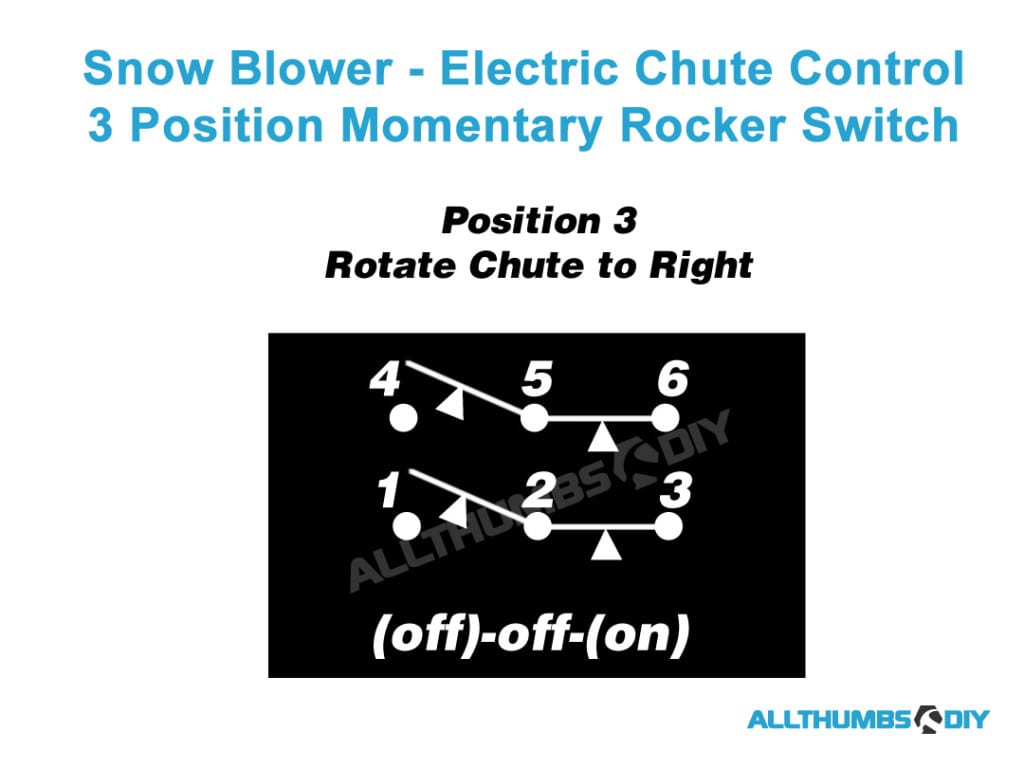

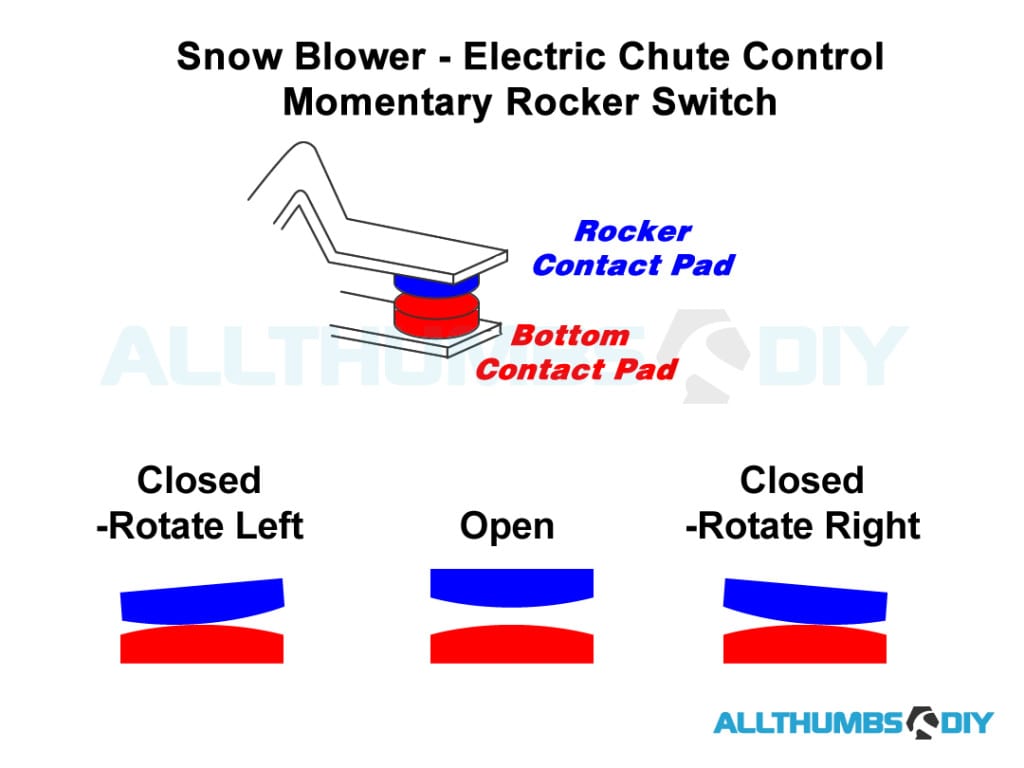

Chute control switch is commonly referred to as DPDT or Double-Pole, Double-Throw momentary rocker switch.

When the left side of the chute control switch is pressed (Position 1), the two small circular pads on two the metal rockers will “see-saw” to the left, make contact with two bottom left contact pads to complete a circuit. This circuit drives the chute motor clock-wise, turning the chute to the left.

When the right side of the switch is pressed (Position 3), same thing happens to the right contact points, but this time the polarity is reversed, driving the chute motor in a counter-clockwise direction, which rotates the chute to the right.

When the switch is released, two rockers return to a “balanced” position (Position 2), which maintains an open circuit.

WHY BENDING ROCKERS/LEVERS IS NOT THE CORRECT SOLUTION

There are lots of videos and forums posts suggesting that bending these two metal rockers inside the switch will restore the chute control and indeed, chute control seems to return for most people but I am going to suggest that this repair step is simply masking the problem and here’s why:

- Two metal rockers are located inside a sturdy plastic housing. The way switch mechanism is constructed, there is a limited travel distance when a switch is depressed. That means unless the housing is compromised (i.e. cracked) a person simply cannot exert additional force to bend these rockers

- Rockers are shaped like a “W”. How can an almost-1/4″ thick metal shrivel from a “flatter W” to a “taller W”? I say that is physically improbable, given the amount of electricity we are working with

So why does it work after bending? I can think of two reasons.

First, when rockers are removed, some of these surface deposit materials are removed, thereby allowing electricity to flow through again.

Second, when rockers are reinstalled, perhaps they are switched around so that the the surface deposit locations no longer correspond.

In either case, I suggest disassembling, cleaning and applying anti-galling compound.

ROOT CAUSE

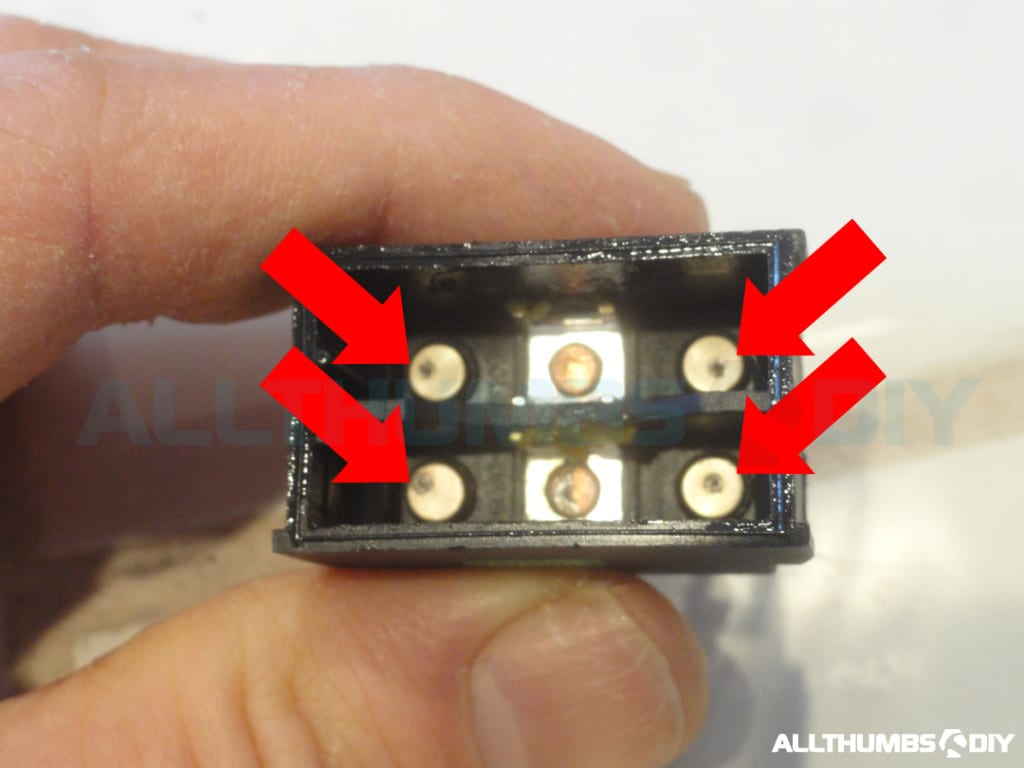

If you take a look at the bottom contact pads as well as contact pads on the rockers, you can see dark dimples and/or surface deposits.

I believe these are byproducts of arcs, sparks and galling when two contact pads touch each other.

CONNECTORS

Because manufacturers change connectors over the years, it can get little bit confusing so let’s go over some basic connector types.

Blade connectors – A blade connector is a type of single wire connection using a flat conductive blade which is inserted into a blade receptacle. Usually referred to as “Quick Connect Tabs”, Faston (trademarked term owned by TE, formerly known as Tyco Electronics), Fastin, spade, tab or QC terminals.

NEW CONNECTORS

Briggs & Stratton OEM Part # 1687904

Replaces these, older style units:

- Part Number 1754865YP

- Part Number 1752240

- Part Number 1737378

- Part Number 1752240YP

- Part Number 1752240

- Part Number 1737378

- Part Number 1752240YP

- Part Number 1737378YP

- Part Number 1737378YP

Briggs # 1687904, original wire harness adapter kit (UPC 047282108871), come with a new AMP / Packard 580 connectors. The kit includes:

- Rocker switch with imprinted label (see pix for new labeling; different than the original)

- Wire Harness adapter (Euro-look to AMP/Packard)

- 2, small zip ties

- Instruction pamphlet (Installation pamphlet in PDF version is available here)

Carling Technologies VCH-01 8 Position Contura Switch Connector Housing

- Carling Technologies – VCH-01 Contura Accessories (external link to mouser.com, PDF

External Reference Links

- Carling Technologies – Termination

- Cole-Hersee / Littlefuse – Sealed Rocker Switches Specs

- Electrical Switches – Ingress Protection (external link to OMROM; click here)

- Pole and Throw (external link to OMROM; click here)

- Carling Technologies – Poles in rocker switches explained

- Carling Technologies – Termination explained

- DPDT – short for double pole, double throw, it is composed of two-poles, two-throw relays. Double pole means that the unit contains two identical switches, side by side, and operated by one single toggle or lever. This means that two separate input wires can be controlled by a flick of one toggle. Single throw means that each switch can make or break a circuit; it can connect the input wire to the output, or not. It can’t connect to one or other of two output wires, switching between them. A DPDT switch is also used for a disconnecting a 240 volt supply from a 240 volt load. Some other types of switches are Single Pole Single Throw (ordinary light switch), Single Pole Double Throw, Double Pole Double Throw, Triple Pole Single Throw and Triple Pole Double Throw

- Rocker Switches – Rocker switches provide a way to switch on and off your electrical circuits. Rocker switches come in either two function, such as an ON-OFF switch, or three function such as an ON-OFF-ON switch. For each function, the switch can be either a single pole, or double pole switch. A double pole rocker switch is basically two switches in one so that you can operate two circuits with a single switch. And finally, each switch function can be either ON, OFF, or MOMENTARY operation. MOMENTARY operation means that when your finger is removed from the switch, the switch goes back to the OFF position. Connections on the back of the rocker switches is usually made using 1/4 inch push-on terminals. An ON-OFF rocker switch will have a terminal to connect to your battery or source, and a second terminal to connect to your load or accessory. An illuminated rocker switch will have an extra terminal to connect either a ground wire or common wire to allow the indicator light to illuminate. A three terminal rocker will have a terminal to connect your source, and two terminals for the two loads the switch will operate. A double pole rocker switch will have either 4 or 6 terminals on the back.

- Galling – Galling is a form of wear caused by adhesion between sliding surfaces. When a material galls, some of it is pulled with the contacting surface, especially if there is a large amount of force compressing the surfaces together. Galling is caused by a combination of friction and adhesion between the surfaces, followed by slipping and tearing of crystal structure beneath the surface. This will generally leave some material stuck or even friction welded to the adjacent surface, whereas the galled material may appear gouged with balled-up or torn lumps of material stuck to its surface.

- Carling Tech – eLibrary

FINAL WORDS

If you found this article to be useful, can you do me a favor and sign up for my newsletter? The signup form is found at the top of the screen on the right side.

Good luck with your repair and let me know how it turns out!

Brad Barth

Thursday 29th of December 2022

I am finding satisfactory performance of the OEM switches not by bending or anything just by cleaning the contacts. If these switches are made in china or whatever why aren't they more available and affordable? I don't really want an $80 conversion kit if I can just have a set of spare OEM switches and clean them before each season starts. Then I'd be fine.

kevin

Thursday 29th of December 2022

Hey Brad,

Unfortunately, due to supply chain problems with China, replacement switches are very expensive.

You may want to check your local Facebook Marketplace and Craigslist...

David Marshall

Friday 18th of March 2022

Can’t find the sign up part of top right. Thanks for putting this out. I am looking for the wiring of the chute control. Specifically I need to know if the chute motor is defunct. I replaced the chute switch but still doesn’t work. Any suggestions?

The Ultimate Resource Guide for John Deere 1330SE Snowblower — AllThumbsDIY.com

Monday 8th of February 2021

[…] How Does Electric Chute Switch Work on a John Deere 1330 SE Snowblower […]

Craig

Thursday 29th of August 2019

Do you have a part number for the chute deflector rocker switch?

kevin

Friday 11th of October 2019

the rocker switch for both functions are the same. the post should have the part number

Craig

Friday 22nd of February 2019

Kevin, If I bought a Cole Hersee Mom On-Off-Mom On Rocker Switch DPDT - M-58031-09-BX, would it fit in the original 1330 SE slots? Also, do they sell the harness, or would it just be best to pay the money and get the B&S Switches and Harness for both sides? Thanks, I appreciate your time. Craig

kevin

Sunday 3rd of March 2019

Hi Craig-

Cole Hersee switch will probably work but since it does not come with the harness, you might be better off buying the kit from B&S.

Let me know if you still need to buy one and can't find it. I think I have a spare kit I can sell