Key Points

- Step-by-step instructions on how to troubleshoot and replace a GE Refrigerator main control board

- Instructions on installing Part # WR55X10956 and WR55X11064

Table of Contents

- Applicable Models

- Location

- Maintenance – Visual Inspection Tips

- Input / Output Specs

Applicable Models

| GE Model | Part # | Name | Replaces |

|---|---|---|---|

| PFCF1NFW (PFCF1NFWAWW PFCF1NFWABB PFCF1NFWASS) | WR55X10956 (Check here for the latest availability and price) | Main Control Board Assembly (computer logic board) | 1550509, AH2371144, EA2371144, PS2371144, WR55X10657, WR55X10658, WR55X10662, WR55X10697, WR55X10745, WR55X10774, WR55X10929, WR55X10943, WR55X10958 |

| PFCS1NFW | See PFCF1NFW | Main Control Board | See PFCF1NFW |

| PFIC1NFW | See PFCF1NFW | Main Control Board | See PFCF1NFW |

| PDCF1NBW | See PFCF1NFW | Main Control Board | See PFCF1NFW |

| PFCF1NFC | WR55X11064 ** | Main Control Board | WR55X10697 |

| PFCF1NFX | WR55X11064 ** | Main Control Board | See PFCF1NBW |

| PFCF1NFYA | WR55X11064 ** | Main Control Board | See PFCF1NBW |

| PFCF1NFZ | WR55X11064 ** | Main Control Board | See PFCF1NBW |

| PFCF1NJW (PFCF1NJWABB, PFCF1NJWACC, PFCF1NJWAWW) | Main Control Board | See PFCF1NBW |

** You may see a sticker on the backside of your refrigerator that states “ATTENTION: USE ONLY MAIN BOARD SPECIFIC VARIABLE SPEED COMPRESSOR. REPLACEMENT PART NUMBER WR55Xxxxx”. Please note that all part numbers listed in the above table are the latest information obtained directly from GE Appliance Parts.

Location

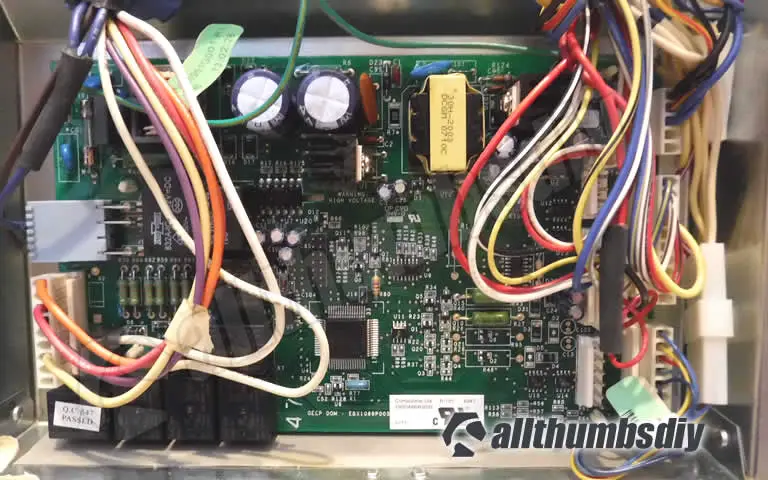

Main control board is only accessible via rear panel of your refrigerator.

Model PFCF1NFW main control board is located on the lower right side. Your specific location may vary.

Please note that the black duct tape you see on the top side of a cover panel was applied by me to prevent any liquid from getting inside the main control area.

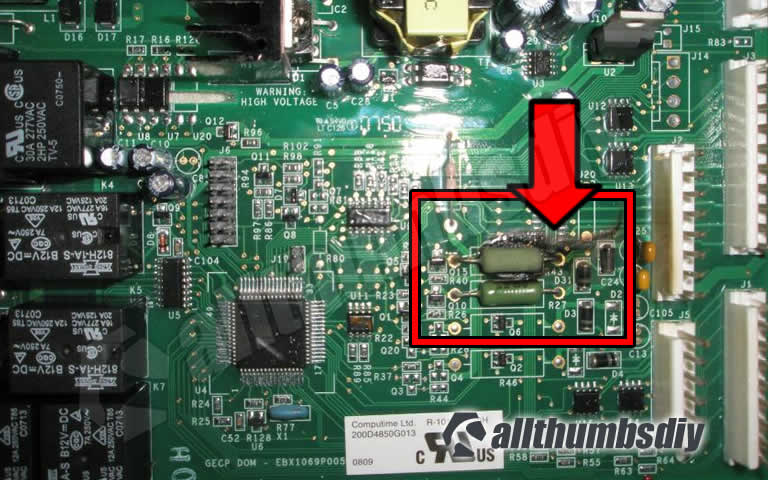

Main Control Board

Show below is the a WR55X10956 board. Depending on your refrigerator model, it might look slightly different.

Input / Output Specifications

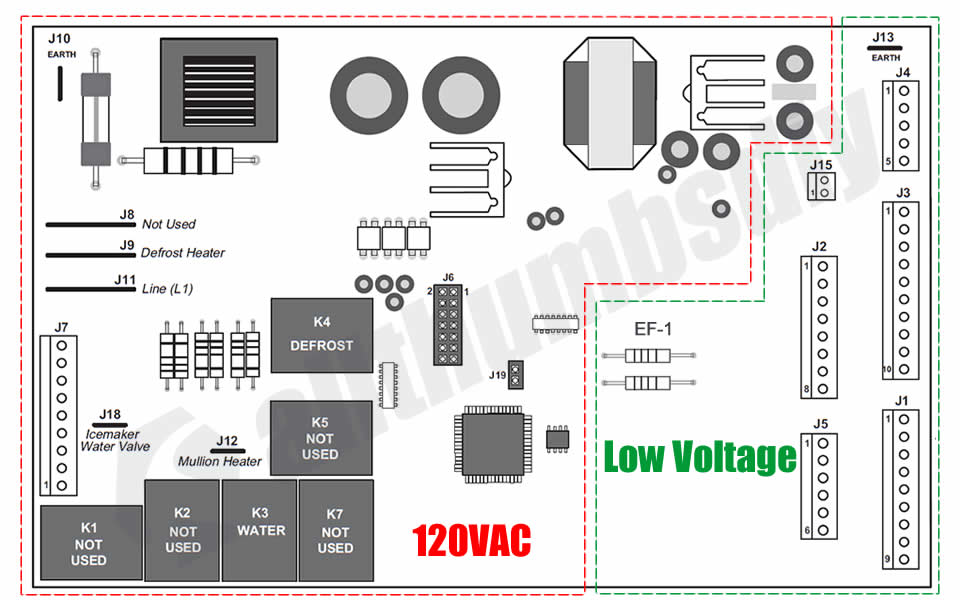

The main control board is divided into 2 sections: Low voltage DC side (right half) and 120VAC side (left half that contains two large capacitors). The sides are on entirely two different circuits (the reason for having two separate green ground wires).

Low Voltage Side

| Jumper | Pin | Description |

|---|---|---|

| J1 (Sensor Input) | 1 | FF Thermistor |

| 2 | Ambient Thermistor | |

| 3 | FZ Thermistor | |

| 4 | FZ Evap. Thermistor | |

| 5 | Thermistor Common +5V | |

| 6 | Not Used | |

| 7 | Not Used | |

| 8 | Model Selector | |

| 9 | Model Selector | |

| J2 (Fan Speed Control) | 1 | Evaporator Fan (RPM, Tachometer) |

| 2 | Model Selector | |

| 3 | Fan Common | |

| 4 | Evaporator Fan | |

| 5 | Condenser Fan | |

| 6 | Mullion Bat Heater | |

| 7 | N/A (Custom Cool Fan on certain models) | |

| 8 | Fan +12V | |

| J3 | 1 | Damper |

| 2 | Damper | |

| 3 | Damper | |

| 4 | Damper | |

| 5 | N/A (not used in PFCF1NFW model) | |

| 6 | N/A (not used in PFCF1NFW model;3 Way valve -Dual Evap) | |

| 7 | N/A (not used in PFCF1NFW model;3 Way valve – Dual Evap) | |

| 8 | N/A (not used in PFCF1NFW model;3 Way valve – Dual Evap) | |

| 9 | N/A (not used in PFCF1NFW model;3 Way valve – Dual Evap) | |

| 10 | N/A (not used in PFCF1NFW model;3 Way valve – Dual Evap) | |

| J4 (Communications) | 1 | Communication 2 Way Digital |

| 2 | Communication +12V | |

| 3 | Communication Common | |

| 4 | Not used | |

| 5 | Not used | |

| J5 (Not Used in PFCF1NFW) | 1 | N/A (Custom Cool models only; QC Damper 1+) |

| 2 | N/A (Custom Cool models only; QC Damper 1-) | |

| 3 | N/A (Custom Cool models only; QC Damper 2+) | |

| 4 | N/A (Custom Cool models only; QC Damper 2-) | |

| 5 | +5 VDC | |

| 6 | TC Thermistor (Quick Chill model only) | |

| J13 (Earth) | 1 | Ground |

| J15 (Inverter) | 1 | Inverter Output (4-6 VDC) |

| 2 | Inverter Common | |

| EF-1 (Evaporator Fan) | N/A | Resistors (will burn out if the evaporator fan is shorted out) |

High Voltage side

| Jumper | Pin | Description |

|---|---|---|

| J7 | 1 | Not used |

| 2 | Not used | |

| 3 | Dispenser Water Valve | |

| 4 | Not used | |

| 5 | N/A (models w/ Quick Chill Heater) | |

| 6 | FF Light switch | |

| 7 | FZ Light switch | |

| 8 | Not used | |

| 9 | Neutral | |

| J8 | 1 | Not used (supply power to compressor on certain models; PFCF1NFW uses inverter) |

| J9 | 1 | Defrost Heater |

| J11 | 1 | L1 or Line 1 power supply |

| J12 | 1 | Mullion heater |

| J18 | 1 | Ice maker water valve heater |

You should perform periodic visual inspection of your board (top and bottom sides). A healthy board should look something like this:

What your looking for during your visual inspection is to detect any signs of burnt components.

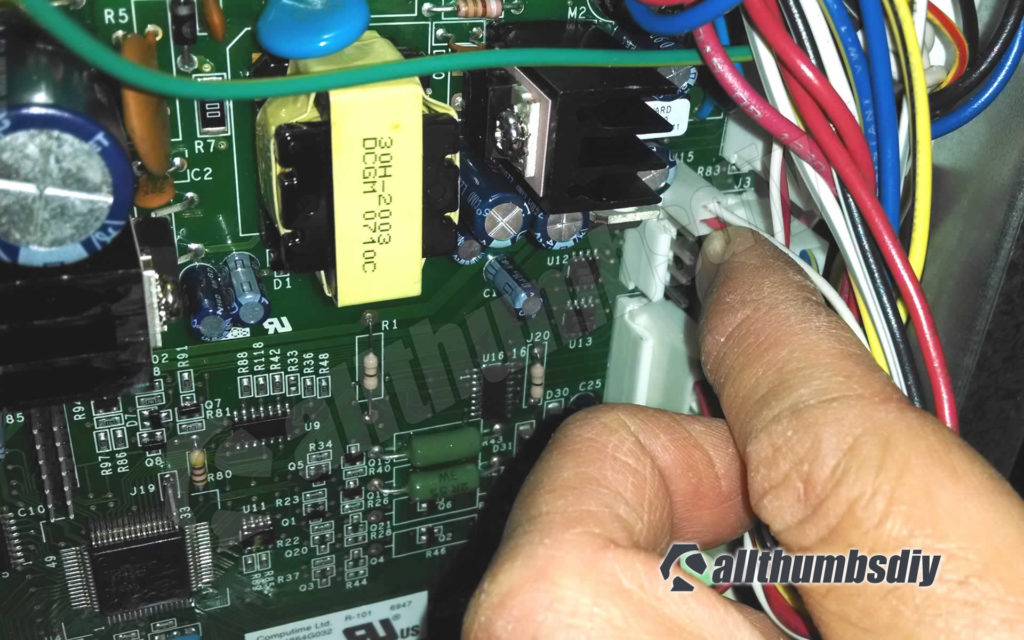

xxxx Some burnt components may only be visible from the underside so you will have to unplug your refrigerator and disconnect all wires and remove the board for closer inspection.

Main Board Tests

- Measuring thermistor resistance at J1 jumper

- Measuring thermistor voltage at J1 jumper

Required Tools / Materials

- 3/8″ socket

- Needles nose pliers

- Multi-meter

- Ziploc bags

- Ice

- Roll of Duct tape

- 2″ zip ties

- 4 thermistors

- 1 defrost heater temperature sensor

J1 Jumper

By the end of this section, we want to confirm that J1 on the main board and all thermistors are in working order

- Verify that thermistor resistance is +/- 5% of 16.3 K ohms or 16,300 Ohms at simulated 32 degrees

- Verify the main board J1/Pin5 is sending +5 VDC to thermistors (warning – if you are not careful, you may damage your board!)

- Verify that each thermistor is returning 2.8 to 3.5 VDC (depending on the temperature) (warning – if you are not careful, you may damage your board!)

| Evaporator Thermistor and Defrost Temperature Sensor |

|---|

| These two parts are tucked away in a very tight space in the freezer so it is almost impossible to test them in place. My recommendation it to test and verify that all other thermistors are in working order and that the main control board is sending a proper voltage. Only then, skip the testing and REPLACE these two parts. At around $15 a piece, they are not too expensive and you will save time and lots of frustration. |

Preparation Work

- Step # A1 – Fill 3 small zip-loc bags with ice and some water and set them aside for ff, fz and ambient thermistors (Pin 4 – evaporator thermistor will be replaced so it will not be tested)

- Step # A2 – Pull out the refrigerator and unplug it

- Step # A3 – Remove the bottom freezer door

- Step # A4 – For the fridge and/or freezer thermistors, remove the plastic shark gill covers by inserting a small flat head screwdriver from the bottom and popping it off; thermistor wire can be pulled out about 2 inches

- Step # A5 – For the ambient thermistor, remove the toe kick plate (below the freezer door) by removing 2 Phillips screws; you will need to cut off the zip tie

- Step # A6 – Dunk each thermistor into a ziploc bag and tape it securely to the refrigerator so that the bag will not spill; wait 5 min

- Step # A7 – Uncover the main control board access panel using a 3/8″ socket

- Step # A8 – Touch bare metal surface (away from the main control board area) to discharge any static electricity

Measuring Thermistor – Resistance

Taking a resistance measurement with wires attached to the main board will produce inaccurate results.

- Step # B1 – Set the multi-meter to “ohm”

- Step # B2 – Detach J1 wire harness block from the main control board

- Step # B3 – Insert the black lead into Pin 1 (FF thermistor) on the wire harness block (not the main control board pin!); we are not testing polarity so it does not matter which lead color goes where;

- Step # B4 – Insert the red lead into Pin 5 (common) on the wire harness block (again, not the main control board pin!)

- Step # B5 – Your resistance reading should be around 16.3 K-ohm or 16,300 ohm

- Step # B6 – Repeat steps #B3 and B4 for Pins 2 and 3;all thermistors are identical so the return resistance value should be very close to each other;

- Step # B7 – If the return resistance value is way off, you can either do additional testing with the refrigerator plugged in (i.e. live voltage) or just replace the faulty thermistor

| WARNING |

|---|

| Although this test section involves working with the low voltage side, you can damage the board, hurt or even kill yourself if you accidentally touch a wrong part! If you are uncertain of your capabilities, please consult a appliance technician. |

Measuring Thermistor – Voltage

Taking resistance measurements with wires attached to the main board will produce inaccurate results.

- Step # C1 – Set the multi-meter to “VDC”

- Step # C2 – Leave the J1 wire harness block attached to the main control board

- Step # C3 – Insert the black lead into Pin 1 (FF thermistor) from the top side on the wire harness block

- Step # C4 – Insert the red lead into Pin5 from the top side on the wire harness block

- Step # C5 – Your return voltage reading should between 2.8 to 3.5 VDC

- Step # C6 – Repeat steps #C3-4 for Pins 2-4; all thermistors are identical so the return resistance value should be very close to each other

- Step # C7 – If the return voltage value is way off, replace the faulty thermistor

Related Links

- Custom Cool Pan Operation – How does it work? (external link, GE)

- TurboCool Operation (external link, GE)

Thomas

Friday 25th of August 2023

What would cause nothing to work in my profile side x side? No lights, nothing. If I pull the J2 plug some of the display works and the compressor fan runs slowly but nothing else.

kevin

Tuesday 5th of September 2023

your CPU is most likely shot