If you are interested in building a backyard swing set yourself, you may want to read my article, How I Built My Own Backyard Swing Set – Part 1

Even without considering the price tags (which were too pricey for me), I saw lots of swing sets with some “features” that I definitely did not like:

- Use of doubled up 2x6s as the main header / beam;

- Thin support beams;

- Use Lag screws to secure load bearing joints and accessories;

DOUBLED UP 2X6s

There is nothing wrong with using doubled up 2x6s as the main beam as they are structurally stronger than using a single piece of 4×6. However, the problem I saw is how swing set accessories are attached to it.

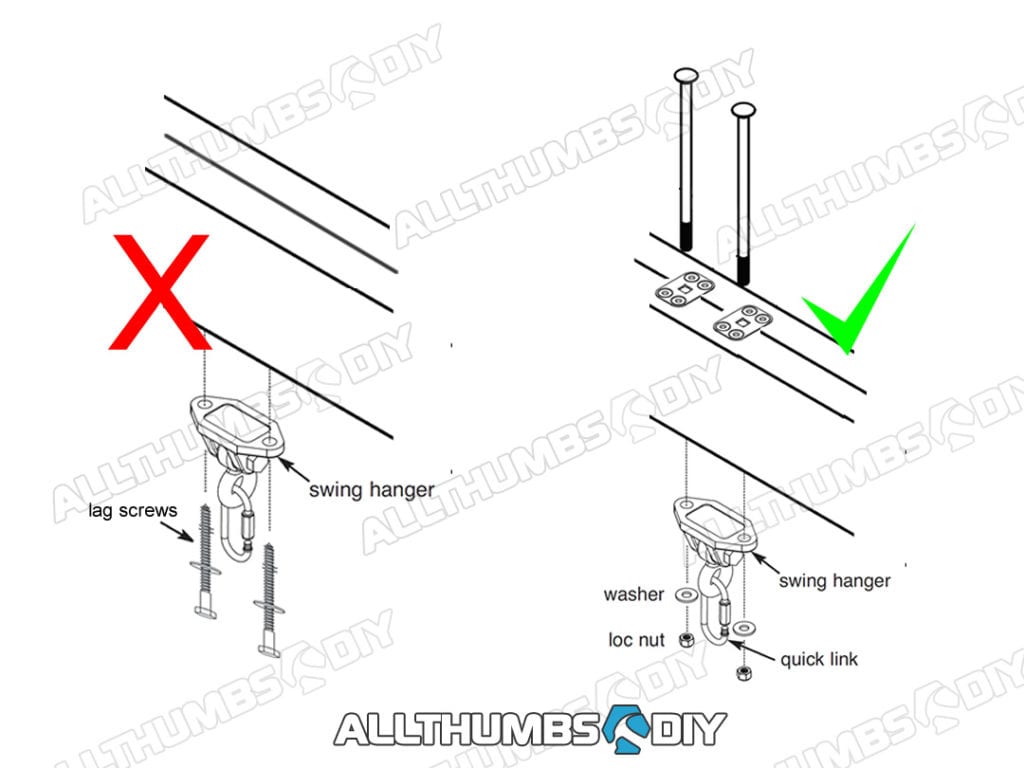

As you can see in the above picture, all swing hardware attachments are done via drilling a hole in the center of the beam. In the case of our doubled up 2x6s, To attach a swing seat or other accessories, we have to drill screw holes in the center of the beam, which meant the screws were installed right in the middle of 2x6s.

I think it would have been fine if bolts and plates were used (figure on the right) to spread the load but I have seen many sets with simple lag screws holding up the hardware. The sandwiched 2×6 joint is also exposed to rain and snow which “could” be a problem if the lumber was not treated properly.

I read some place that 2 swing seats can potentially generate up to 6-8 Gs when swinging in alternating pattern so I think it is very important that we do not skimp on how we attach swing set accessories.

Instead, I scoped out the one I really liked and took some eyeball measurements and will try to replicate it by using pressure treated lumber (instead of red cedar).