With the cold weather fast approaching in the Northeast U.S., I decided to finally replace my leaky basement windows.

I found a basic how-to video at This Old House, but it did not contain any information about a concrete sill that was that built up right up against a basement window so I am going to share what I learned from that project.

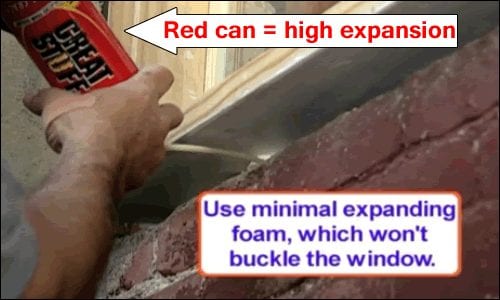

Please note that at the 1:04 mark, a popup states “Use minimal expanding foam, which won’t buckle the window”. But if you look at what Tom is using, it is a Great Stuff in a RED CAN which is not recommended by the maker, Dow Chemical. The correct product comes in a BLUE CAN which is intended to be used in sealing doors and windows.

Introduction

I have done plenty of window replacements in the past but they were all designed to be dropped in (minus few new construction windows with frame enlargements). My biggest worry was that once I started the demolishing mortar and concrete around the window, my foundation wall would somehow crumble.

So what convinced me to try it anyway? Several quotes from local contractors who wanted to charge me on average of $400 per window! In addition, I figured I had enough DIY experience to overcome any challenges. Hopefully you can gain some confidence (and save money) by reading and doing this project yourself.

Assessment

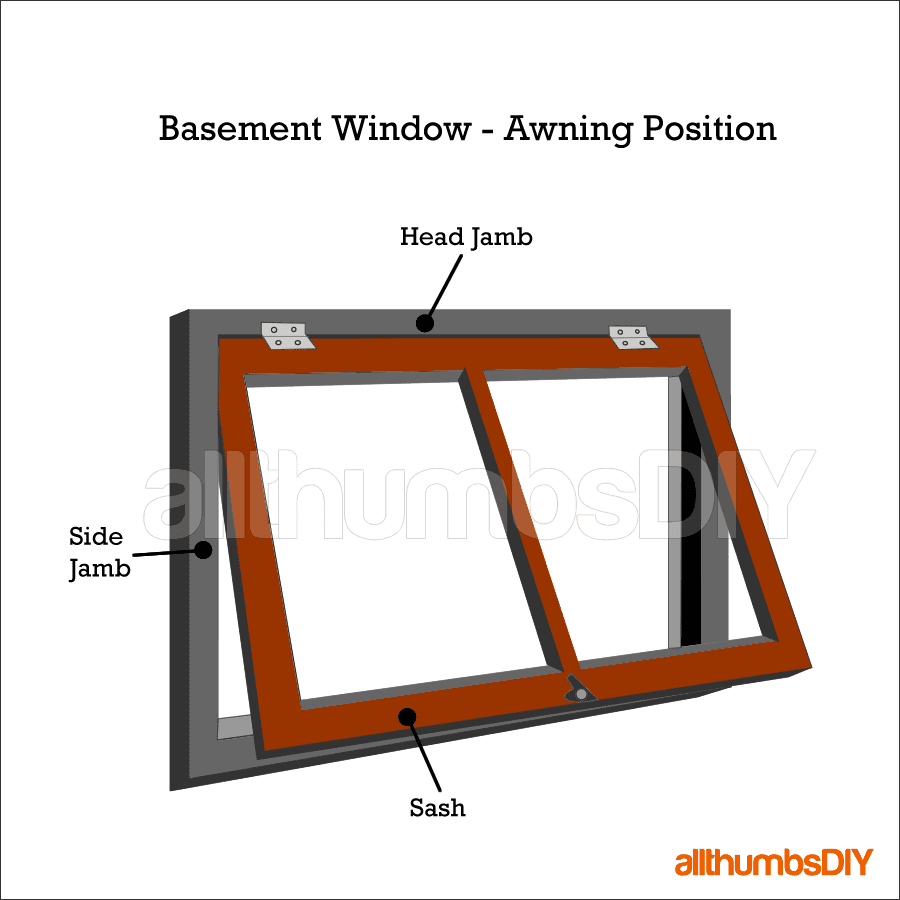

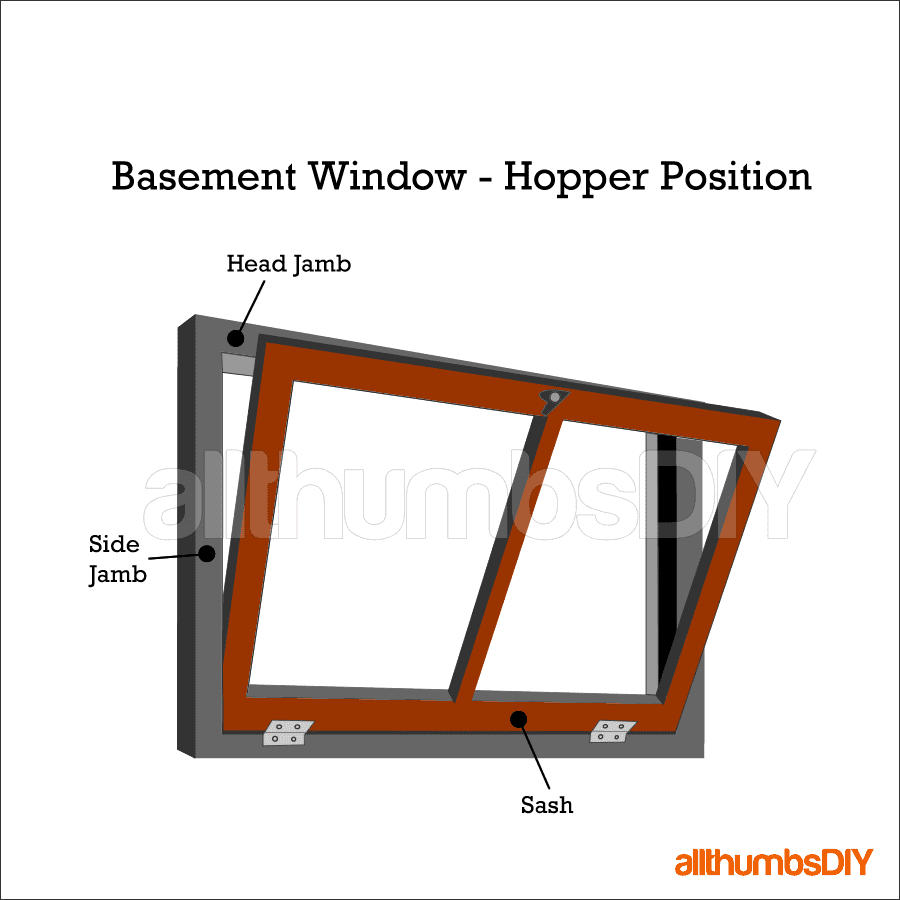

I had to replace total of 4 basement windows. They were the old fashioned awning windows with windows hinged to the head jamb, and opened inward (see fig 5.1 – Awning). My windows frames were set directly on to the concrete foundation, secured by nails to the top head jamb / sill plate and construction adhesive on both side jambs / concrete foundation blocks.

Please purchase a window as intended by a manufacturer because window sills and weep holes are designed to shed water in one direction. For example, it would be bad idea to buy an awning basement window and install it upside down as a hopper basement window.

There were several large gaps around the window frame parameter, which were probably created from years of expanding and shrinking caused by wood frames having direct contact with concrete/mortar (I think concrete and mortar hold moisture which in turn can be absorbed by wood. Any swelling due to moisture and subsequent drying can and will shrink the wood frame).

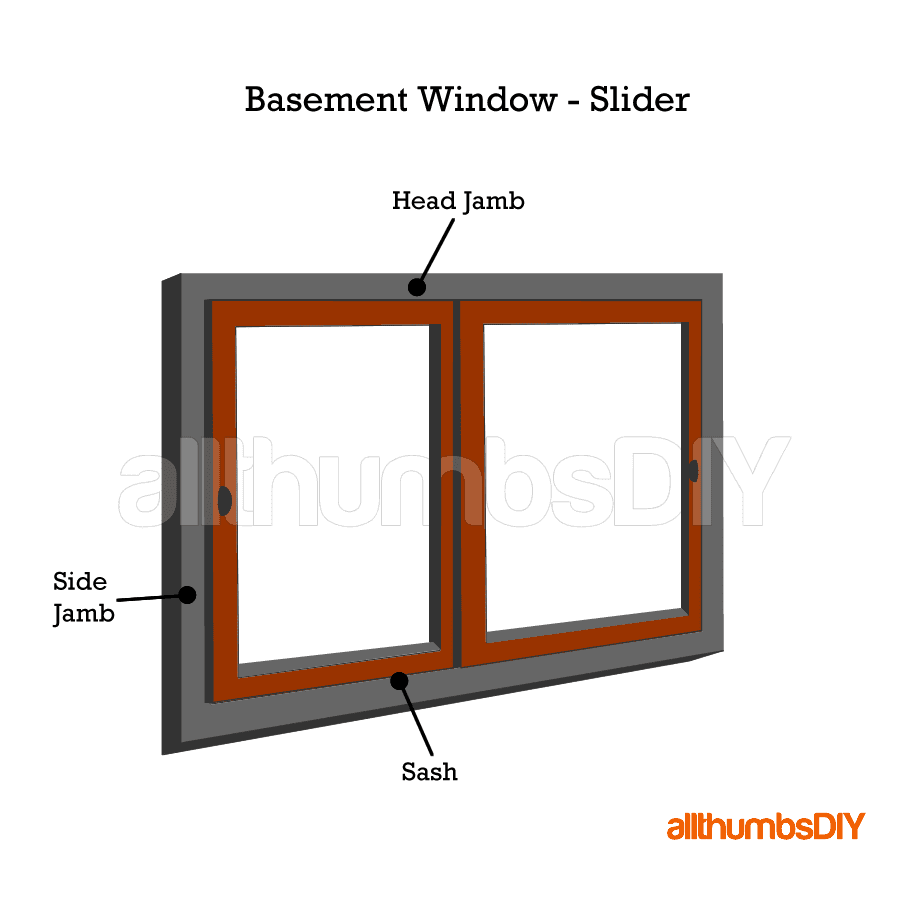

I decided to go with a vinyl basement slider window versus steel or wood (fig.5.3 – slider) because I felt that it would offer better protection against additional moisture (i.e. rain water bouncing off the ground).

Planning

Installing a vinyl basement slider window into a wood frame meant that the glass area would be reduced significantly, resulting in reduced ambient light into an already dark basement. In addition, due to large gaps with air penetration I thought it would be best to completely remove the window frame and install a replacement window directly into the concrete opening.

Before getting started, you should check to make sure that you have all necessary tools and materials before starting this project. There is nothing more frustrating that to to run out to buy tools or supplies while there is a big open hole in a wall.

- Item A, B – Small and large pair of adjustable pliers which are very handy in removing nails where a hammer would not fit. Irwin makes good tools and for less than 25 bucks, you may want to consider IRWIN Vise-Grip Pliers and Wrench 4-piece set

- Item C – Estwing Three Pound Mashing Hammer with Steel Handle – must have item along with a cold concrete chisel; regular hammer will never get the job done because it is simply too light; I highly recommend Estwing because it’s mash hammer is very well made (i.e. balanced) and it is made in the USA

- Item D – good old claw hammer – I would avoid wood and composite handles because they can shatter without warning. Although these handles are lighter, a single forged hammer with a good soft grip will give you the confidence to banging it around. Again, I highly recommend Estwing Curved Claw Hammer

- Item E – Stanley 12 3/4-inch Wonderbar Pry bar is a basic pry bar

- Item F – Stanley 15-inch Super Wonderbar has additional curves to give you added leverage. I would NOT recommend a narrow, hexagonal ripping bar for this job. You need a flat surface area to spread the force. Hexagonal ripping bars might damage more surrounding areas

- Item G – Cordless drill – I have a collection of Ryobi tools (sold at Home Depot) that I have been using for over 6+ years. Other than switching from a NiCad to Lithium batteries, all my Ryobi cordless tools still work perfectly

- Item H – Stanley Fatmax Tape Measure

- Item I – DEWALT Tough Tool Box Medium Case

- Item J – Mayhew Select Mason Cold Chisel with Flat-space and a Hand-guard

- Item K – Cold chisel (pin point) – great tool to initially break concrete lumps; make sure to get one with a hand protector (orange grip); trust me from my experience, you do not want that 4 pound mash hammer landing anywhere near your hands or fingers

- Item L – Stanley Surform Paner – handy tool to scrape off vinyl window corners to flatten out excess bits leftover during manufacturing; it is very important to flatten out these bits because they can distort how a window fits into the opening

- Item M – Work gloves – working with concrete bits by swinging a 3 pound mash hammer can do some major damage. At minimum, buy a leather tipped work glove; better yet, get something like Ironclad Framer work gloves to protect your knuckles and fingers.

- Item N – Eye protection; I forgot to take a picture of it but you must ABSOLUTELY wear eye protection, especially when breaking apart concrete. I recommend Dewalt Contractor Pro Clear High Performance Lightweight Protective Safety Glasses. It fits well and gives great protection coverage area. I sweat quite a bit and DeWalt did a decent job of minimizing fog. I prefer clear lenses because working indoors can be dark.

Purchase

Taking measurement was a straightforward process. Like anything else, please make sure to take THREE separate measurements before placing the order. If you want some basic guidelines on how to measure for a replacement window, read my post “Installing Replacement Windows Part 1 of 3“.

Most vinyl window manufacturers will automatically shrink your dimension by 1/4″ (quarter inch) to allow insulation. That means you need to ensure that your rough opening must be square to allow for proper installation. If your window opening is NOT square, you may have to shrink down your measurements further which might result in larger gap. Please notify the salesperson at the time of ordering of your situation.

Also, please assume that all basement windows are different in size, even if they look identical. There is nothing worse than having a huge hole in a basement wall and find out that your basement window would not fit (not to mention you probably cannot return it for a refund)!

While you are at the store, make sure to ask for any requirements to qualify for tax credits (for example, when I purchased my picture window replacement, I had to order it with a grill to receive the tax credit). In addition, save your sales receipt along with any brochures containing the window performance data.

Next Steps

In my next post, Replacing Leaky Rotted Basement Windows – Part 2 of 3, I show you tools and methods I used to removed the wood frame and exterior mortar sills.

Trish

Sunday 22nd of November 2020

Interesting! Not run into this with current home. We live in a mid-century home that's all brick and the original aluminum windows but the sills are wood in the house. We have some movement and around some windows, we need to repoint the concrete between the bricks.

Thanks for sharing.

scott

Wednesday 30th of May 2018

Specifically, who did you order your windows from? I've been in the big box stores and their stock windows all have the "nailing flange" around the outside and the only way to remove it is to cut the entire thing. That's nuts plus you don't know if you'll screw up the window.

Thanks for this. Wonderfully documented.

kevin

Wednesday 30th of May 2018

@ Scott-

Windows with flanges are for new construction or when you tear down the sidings. Ones I got (without flanges) are drop-in replacement windows.

I special ordered mine from Lowe's

Good luck! Kevin

joe juliano

Wednesday 14th of September 2016

have basement window that has wood sill not concrete and now the wood is rotten and leaking .the window is in great shape but the wood sill is rotten . so how do you replace a wood sill and build with a concrete sill????

kevin

Thursday 15th of September 2016

@joe-

in my case, a concrete (most likely mortar) sill was layered on top of the wooden sill. i first had to chip away this layer to remove my sills.

since your window is in good shape, i would visit a local lumber yard and replace those rotted sills with either cedar (expensive) or an engineered fiber-trim (plastic+wood combo) material, along with the tools i mentioned in the article to proceed.

good luck and let us know how you make out!

Butim

Friday 2nd of October 2015

What size did you get your windiw. Based on the picture, I have the exact same basement window

kevin

Sunday 4th of October 2015

@Butim-

My window size (measuring from end-to-end- frames) is 34.75" wide and 18" high.

You really should measure your own, using the methods I used, NOT eyeballing it.

chris

Saturday 21st of June 2014

Everything went smooth. It ended up going the exact same way yours did.except my wood was so rotted it was able to take out by hand. And the mortar was so brittle it cracked with one swing. I used regular insulation instead if foam. Thanks again for the wonderful walk through and giving me the confidence to tackle it myself