The purpose of thread sealant tape (a.k.a. “Teflon tape”) or pipe dope is threefold:

- First, the lubricant qualities allow male threaded pipe to be turned deeper into female threaded fittings to prevent leaks;

- Second, it acts as a filler to smooth out micro abrasions or surface irregularities on threads;

- Third, it keeps the male and female threads from rusting together (a.k.a. seizing)

Top

PIPE THREAD TYPES

AN thread is a type of fitting used to connect flexible hoses and rigid metal tubing that carry fluid (it stems from a joint standard by the U.S. Army and U.S. Navy, hence “AN”).

AN thread provides a positive seal that should seal correctly with specified torque torque range with no leaks. The AN should not require a thread sealant.

National Pipe Thread (NPT) taper is a U.S. standard for tapered threads used on threaded pipes and fittings.

In contrast to straight threads that are found on a bolt, a tapered thread will pull pipes and fittings tight together, providing effective seal for pipes transporting liquids, gases, steam and other fluids.

Although SAE and ASTM (organizations that set U.S. industry standards) set very precise thread class specifications, many threaded products carried by large box retailers have varying degrees of deviations from set specifications (i.e. micro surface imperfections like chatter or spalling), thus requiring a use of thread sealants.

USE SETTINGS

In a residential home environment, we are primarily transporting non-caustic substances like water, natural gas, Liquified Petroleum Gas (LPG), fuel oil (and maybe compressed air and oxygen).

Although there is no hard and fast rule, we can broadly categorize residential threaded joints as either permanent or semi-permanent joints to identify appropriate applications for thread sealants:

Permanent Joints

Any joints which would normally be installed during the rough-in or stack-out phase of the plumbing and which could be reasonably expected to last the lifetime of the structure. These would include galvanized iron water lines, threaded connections on main & zone valves on the water distribution system and gas lines.

The recommended product is a pipe joint compound (a.k.a. pipe dope)

Semi-permanent Joints

Any joints which we typically make during the final trim out phase such as fixture angle stops, shower arms, shower heads, tub spout to the stub outs or any joint which we could reasonably expect may be changed periodically for general maintenance or aesthetics purposes during the life of the structure.

The recommended product for this application is a sealant tape (a.k.a. PTFE or Teflon tape)

PTFE THREAD SEALANT TAPES

When a thread seal tape was first introduced, it only came in a single density type as a white Teflon tape(1) that was commonly found in large home improvement stores.

Later they began making a double density version, which was twice as thick in the same color (unfortunately with the same “white” color).

(1) Teflon tape is used ubiquitously when referring to a thread sealant tape. However, the word “Teflon” is a trademark name owned by Dupont Chemical Corp. Although Dupont no longer manufacturers Teflon tapes, it still enforces its trademark rights. That is why you see other manufacturers like Oatey refers to it as PTFE (PolyTetraFluoroEthylene) thread sealant tapes.

One very important thing to remember is that PTFE thread sealant tapes and pipe joint compounds are only to be used on NPT male threads.

Neither products should be used on NA or SAE mechanical threads or as a gasket sealer (i.e. sink basket gasket).

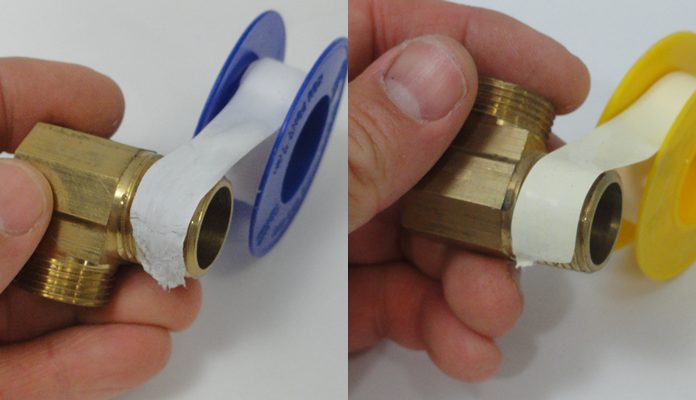

PTFE THREAD SEALANT TAPE COLORS

Since many state and local codes adopted the use of double density tapes when making connections for natural gas, the use of same color for two different thickness presented a challenge when time came to inspect a job. Thus, a “yellow TEFLON tape” was later introduced for such application.

Since then, ASTM has broadened the specifications for PTFE tape colors.

White Sealant Tapes

Commonly used in water pipes, a white sealant tape consists of either a single or double density and should only be used on NPT threads up to 3/8 inch in diameter.

- Suggested product – Lasco White PTFE Pipe Sealant Tape, 1/2 inch x 100 inch (approximately 8.4 ft)

Pink Sealant Tapes

Pink thread sealant tape consists of triple density material, considered to be heavier duty than white sealant tapes. Pink tape is intended to be used in joining water pipe connections with larger diameter pipes. Many plumbers use pink water sealant tapes instead of white because of its thickness.

- Suggested product – Oatey Water-Line Thread Seal tape, 1/2 inch x 260 in (approximately 21.7 feet)

Yellow Gas Sealant Tapes

Yellow sealant tape is intended for natural gas (or any other gaseous materials) pipe applications. It consists of a double density material that feels more “oily”.

- Suggested product – Oatey Gas-Line Thread Seal Tape, 1/2 inch x 260 in (approximately 21.7 feet)

Green Sealant Tapes

Green sealant tape is a very thick tape (3.7 mil) intended for any pipes carrying oxygen (i.e. medical oxygen or welding oxygen lines).

- Suggested product – Gasoila Green Thread Tape 1/2 in x 260 in (approximately 21 feet)

PIPE DOPE / LIQUID THREAD SEALANT

Pipe dope, technically known as pipe joint compound, is both a thread lubricant and thread sealing compound.

Unlike a thread sealant tape, pipe dope is designed to make a pipe thread joint leak proof and pressure tight by brushing on a pasty substance to a male thread.

You should never apply a pipe dope to a female thread because some of it will push into the pipe, possibly causing the pipe to clog.

Some people use pipe dope on top of thread sealant tape but many manufacturers say there is no added benefit to that setup.

Pipe dope itself can be classified into 2 distinct categories:

Oil-Based Pipe Joint Compound

- Usually comes in a dark gray paste designed to work on all metal based pipes and fittings

- Suggested Product – Oatey 8-Ounce Pro Dope Joint Compound

Non Oil-Based Pipe Dope

- Usually comes in yellow paste that works with all metal and PVC-based pipes

- Suggested product – Rector Seal 4-Ounce Yellow Pipe Thread Sealant

Pipe Joint Compound / Pipe Dope Tips

- While there are number of pipe dope product on the market, the one that seems to be most widely accepted by plumbers, pipe fitters, HVAC techs and electricians is products from RectorSeal

- RectorSeal has a handy chart explaining their comprehensive thread sealant products (click here to download a PDF from AllThumbsDIY.com)

- You can obtain more product-specific from Rector Seal products by clicking here

- If a pipe thread will be exposed to extreme temperatures, a better suited product might be a liquid thread sealant called Permatex White Thread Sealant with PTFE 4-Ounce which has the same sealing capabilities as Rector Seal but it is designed to work in a broader range of temperatures (-60 to 300 F).

TIPS TO REMEMBER

- The main purpose of a thread seal tape / liquid thread sealant is to seal out micro abrasions or surface irregularities on threads. If you have a major gash or nick on a thread, you will need to replace the pipe section or re-thread it, rather than applying a thicker seal tape layer

- Applying more than 3 layers of sealant tape is not recommended

- When starting out, make sure the seal tape is not covering the pipe opening. Any exposed seal tape may break loose over a period of time and cause a blockage problem; in the future;

- Pipe connections generally turn clock-wise but there are instances when that is not true (i.e. gas pipe union joint). Always test out and make a note of the pipe rotation before applying the tape and remember that the tape application must “go with the flow”;

- You cannot connect dis-similar pipes together (i.e. copper-to-steel) and hope that a thread sealant tape will prevent from interacting with each other, possibly causing corrosion problems. In this situation, you must use a dielectric union (something like this)

- If you need a gasket sealer, you may want to checkout can use hyolomar based products like Valco Cincinnati Hylomar (blue compound sealant 250 ml) or Permatex Ultra Black Maximum Oil Resistance RTV Silicone Gasket Maker

SUMMARY

So what do I use in my plumbing projects?

I tend to apply both the sealant tape and pipe dope if there is plenty of space around the pipe I am working on or if I am working with black steel pipes (generally used for natural gas) because their threads tend to be rougher.

If the working space is tight (let’s say a 1/2″ water pipe straddling a floor joist), I tend to go just with pipe dope. I only use sealant tapes for drink water supply lines (i.e. kitchen sink).

Head on over to my post “How To Correctly Apply Teflon Tape to a Thread” to see some application-specific examples.

Thanks again for reading my post and good luck with your DIY project!

Jim

Wednesday 24th of October 2018

Can I use white tape for a gas dryer connection?

George Lentz

Saturday 12th of May 2018

If you would turn the roll of tape over. Place your first finger on the end of tape to the threads then bring the roll up and over threads for three rounds You are in better control and do a better job.

Kirk

Thursday 4th of January 2018

Can I use yellow tape on water pipe?

kevin

Thursday 4th of January 2018

@ Kirk-

I would not. Yellow tape is thicker that is suitable for more coarse threads. use the white tape on water pipe threadding

Tim

Saturday 24th of June 2017

I am connecting an "H" burner to a stubbed & capped, ready to use natural gas supply line to the fireplace in my living room. The gas line and fire place are new construction and neither have ever been used. The "H" burner is also new and is appropriate for use with natural gas.

Question: Is it OK to use yellow gas tape instead of pipe joint compound to connect the final connections inside the fireplace on this installation ?

Many thanks for any guidance here.

kevin

Saturday 24th of June 2017

@ Hi Tim-

I believe Oatey tape is rated up to 500 degrees but I am uncertain if it was meant to be used in direct flame.

You should contact your local plumbing inspector to determine the correct method of sealing your H burner

Thanks

Kevin

Kelly

Friday 5th of May 2017

I recently helped my sister move into her duplex where the existing gas connection for the dryer was not in code. I replaced the gas line coming off of the existing valve where the gas shutoff was located. I used a flexible conversion gas dryer kit with appropriate connectors. I also used yellow teflon tape at all the connections and soaped to make sure there were no leaks when done. Within 2 days the gas smell in her duplex was so intense, she called DTE gas to investigate. They came in and said that the yellow teflon "gas" tape should NEVER be used and this was the source of the leak!!! Why would places ever sell this to the public if it's not supposed to be used to seal connectors?

kevin

Sunday 7th of May 2017

@ Hi Kelly-

Sorry to hear about that. I think the use of tape is dependent on where you live and even, which gas company you deal with.

For example, when I worked with my gas company, they told me to not use any tapes when joining "black (supply) pipes" but that I could use the tapes when connecting the last leg of the supply pipe (post shutoff valve) to the appliance.

Kevin